Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

Introduction

On September 21, 2025, the world’s attention turned to the gleaming curve of the newly unveiled Tesla Cybertruck, as electric‑vehicle (EV) sales in the United States leapt 30% from the previous year. The same day, the European Union announced a sweeping revision to its green‑energy roadmap, promising €40 billion in subsidies for EV adoption across all member states. The result: a surge of consumers eager to switch from fossil‑fuel cars to clean, quiet alternatives. Behind every quiet whir of an EV, however, lies a complex system that ensures smooth acceleration, efficient braking, and reliable torque conversion—the gear motor, or reducer motor. In this article, we explore the intersection of today’s massive EV push and the role of gear motors, showing how these compact powerhouses are poised to scale with the planet’s shift toward electric mobility.

EV Adoption: A Market Driver for Gear Motor Demand

The latest trend reports that more than 8.5 million EVs were purchased worldwide in 2024—a figure that ranks second only to passenger aircraft in global carbon‑reduction impact. Governments in the United States, EU, China, and India are tightening emission standards and offering tax incentives, resulting in a dramatically shortened payback period for EV investments.

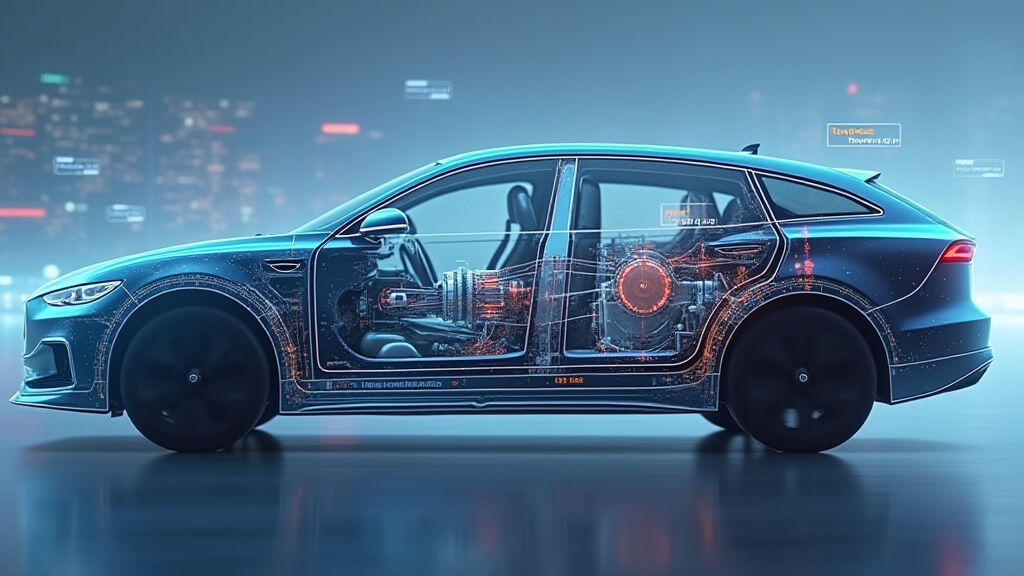

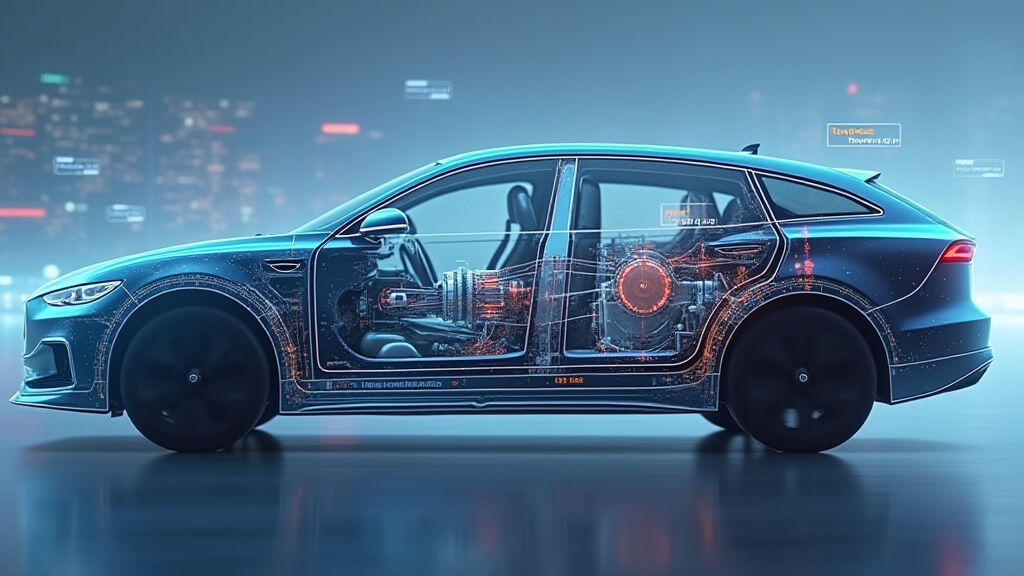

Yet, increased EV numbers require more reliable and efficient drive‑train components. Conventional combustion engines rely on the internal combustion cycle, but EVs use electric motors that produce peak torque or revolutions per minute (RPM) at vastly different points. A simple electric motor cannot directly match the torque required by a car wheel at low speeds; instead, manufacturers use a gear motor to step down the motor’s high-speed, low‑torque output to a low-speed, high‑torque format that wheels demand. This conversion is critical for acceleration from a stop, hill climbs, and maintaining stability during high‑speed driving.

Technological Advances: Modern Gear Motors in EVs

Recent years have seen a shift toward high‑performance, lightweight gear motors. The traditional planetary gearbox is giving way to supplied kinematic drives that incorporate steel alloys and precision machining to reduce backlash and increase efficiency. Modern gear motors can reach efficiencies above 95%, a crucial metric for battery‑powered vehicles seeking longer ranges.

One of the groundbreaking developments is the integration of brushless DC motors (BLDC) with planetary gear reductions. By combining high‑speed, low‑torque BLDC units with a ratio of 9.5:1 or 12:1, manufacturers achieve a wide operating speed range while maintaining the smooth, quiet operation that EV riders expect. Moreover, the compactness of newer gear motors allows the entire drive‑train to fit into tighter spaces, freeing up valuable under‑car space for battery packs or additional harnesses.

In addition, many suppliers are incorporating active-pulley technology, where the gear ratio can be actively adjusted via a low‑voltage control system. This allows the motor to start at low torque for an effortless acceleration and then shift to a higher torque mode for heavy‑load driving—all without sacrificing energy efficiency or introducing mechanical complexity.

Industry Development: Gear Motor Suppliers Step Into the EV Spotlight

Companies that once supplied gear motors primarily for industrial automation are now expanding into the automotive sector. For instance, NordDrive Inc., a European gearmotor pioneer, rolled out a new line of 12‑speed, 10 kW gear motors specifically aimed at mid‑size EVs. Their panels feature integrated sensor arrays that send real‑time position data to the vehicle’s ECU, ensuring perfect synchronization between motor and wheel.

Similarly, the Japanese firm FujiTech has launched a modular “FlexDrive” system utilizing a micro‑gear system that can be swapped out for electric scooters or small passenger cars—effectively future‑proofing products as different EV segments merge.

Because the automotive supply chain has long demanded high precision and tight regulations, gear motor manufacturers have had to meet rigorous standards, such as ISO 26262 functional safety and ISO 9001 quality control. While the learning curve was steep, the rewards are limitless: the EV market is expected to grow at a compound annual growth rate (CAGR) of 20% until 2030. This explosive growth creates a need for more robust, more efficient gear motors.

Environmental Impact: Eco‑Friendly Gear Motors

Gear motors are more than just convenient; they are essential for reducing vehicle greenhouse gas emissions. By stepping down the motor’s speed with minimal power losses, gear motors minimize the energy required from the car’s battery for a given torque output. This compression efficiency translates directly into fewer battery cells and, consequently, less mining and processing of lithium and cobalt—two materials that pose environmental and geopolitical concerns.

Furthermore, gear motor manufacturers are now using recycled aluminum alloys and high‑performance polymers that require fewer energy-intensive processes. Combining these material advances with lightweight design results in motors that weigh critically less than their traditional counterparts, further reducing the vehicle’s overall mass and improving energy consumption.

Future Outlook: From Suburban Commuters to Autonomous Fleets

As autonomous vehicle (AV) technology gains ground, gear motors will play a pivotal role in robotic‑controlled systems. The AV industry demands high precision, dynamic torque control, and robust fault tolerance—capabilities that modern gear motors deliver. A mid‑size autonomous van may rely on multiple gyroscopic‑controlled gear motors to achieve smooth navigation, precise steering, and rapid parking.

In addition, the rise of electrified public transportation, such as e‑buses and e‑trains, indicates another growth area. Gear motors able to operate at high rpm intervals and manage heavy braking through regenerative systems are already being tested in prototype e‑buses, boosting the sector’s energy efficiency.

With the possibility of an upcoming global agreement to phase out internal combustion engines by 2035, gear motors will be the backbone for billions of wheels worldwide. Designers are now exploring “gear‑motor hybrid” concepts, where a small electric motor supplements a traditional combustion engine, providing instant torque during starts and improving overall fuel economy—an interim solution before an all‑electric future.”

Conclusion

The current wave of EV adoption has already disrupted the transportation sector, and gear motors—once merely a background component—are emerging as critical enablers in the transition toward a cleaner, quieter future. As governments continue to incentivize electric vehicles and industry pushes for more efficient powertrains, the demand for high‑efficiency, high‑speed gear motors will grow in tandem. Gear motors exemplify the invisible yet indispensable engineering that powers today’s green revolution. Their compact, efficient, and increasingly smart design ensures that they will not only meet the demands of the present EV market but also be the sturdy foundation for tomorrow’s autonomous, electrified fleets. With each shift in a gear motor’s ratio came closer to unlocking the full potential of electric mobility—and the future looks efficient, sustainable, and remarkably quiet.

Leave A Reply

Your email address will not be published. Required fiels are marked